The mash vessel is a 60 quart Vollrath pot. I purchased the pot (and lid) from Something's Brewing, 196 Battery Street, Burlington, Vermont 05401, (802) 660-9007, Somebrew@aol.com. I had P.B.S. modify the Vollrath pot to include,

One bottom drain is used to recirculate wort to the top of the

grain bed and the other bottom drain is used to drain wort to

the boil vessel.

It is important to be able to transition from dough-in to recirculating and from recirculating to sparging without having to "rearrange" the plumbing. This design allows the dough-in and sparge water (from the sparge vessel) and recirculated wort (from the mash vessel) to be transferred to the top of the grain bed. The ring is adjustable so that it can sit on the top of the grain bed regardless of the quantity of grain.

The original Vollrath lid was cut approximately in half. A piece of stainless steel piano hinge was spot-welded to the two halves.

The ring is suspended from a 3/8" stainless steel round bar. A 3/8" stainless steel Swagelock compression fitting is used to hold the round bar in place. The compression fitting had to be "drilled out" in order to allow the round bar to pass. One nut of the compression fitting was removed and the remaining assembly was passed through a hole in the lid. The nut was replaced to secure the compression fitting to the lid. This nut can be tightened (loosened) by hand in order to adjust the height of the ring.

Note that the sparge ring design involves a single cross member.

The cross member is parallel to the hinge of the mash vessel lid.

This allows for the grist to be easily stirred with the ring in

place and the lid open.

The mash float switch is a Madison M8000 Liquid Level Switch purchased through Grainger for $10. The M8000 is a polypropylene, magnetically actuated, dry reed switch rated to 221º F.

The mash float switch is mounted just above the plane of the sparge ring.

I think that the use of a mash float switch is one of the most

practical aspects of the brewing system. Sparging is truly hands

free. The float switch seems to have a natural differential so

that the pump isn't overly stressed (being turned on and off too

frequently). The switch could be wired in line with the pump in

a non-computer controlled application.

The temperature sensor and thermowell are described as part of

the Sparge Vessel.

The RIMS tube is comprised of the following components.

All of the components are 304 stainless steel.

The electric heater element is a Chromalox Electric Water Heater Element SGW2457X1, 4500 watts at 240 volts, purchased through Grainger for $20.

You'll find that a lot of RIMS articles suggest the use of a 1" N.P.T. fitting to accept the electric heater elements 1" N.P.S.M. threads. N.P.T. fittings are tapered. N.P.S.M. threads are straight.

A 1" N.P.T. fitting will work in some situations. You'll find that water heater elements have very few threads. This coupled with the fact that you will typically use some form of washer, tends to make the "taper" less significant. For example, I use a 1500 watt, 120 volt heater element which has four threads. The washer covers at least one. Copper fittings can be cut "short" or reamed using the heater element to minimize the taper.

As described above, I used a 1" N.P.T. fitting on the RIMS tube (after having successfully used a 1" N.P.S.M. fitting on the sparge vessel). Before the whole assembly was welded, the heater element seemed to thread into the fitting. But after the assembly was welded, I couldn't get a single thread into the fitting. Fortunately, the sheet metal shop that did the welding had a 1" male tap and was able to widen the fitting to accept the heater element.

A 1" N.P.S.M. fitting is certainly the fitting of choice.

I purchased the mash screen from David Stoelting after he ceased making brewing equipment at a slightly reduced price.

Unfortunately, I greatly underestimated how difficult it would be to cut the Stoelting mash screen to fit my 60 quart Vollrath pot. David Stoelting didn't offer much insight into the difficulty either. I ended up having the mash screen professionally cut using a laser ($$$).

I prototyped my brewing system using a 40 quart Vollrath pot with P.B.S.'s stainless steel "strainer". I believe the strainer was an 18 gauge stainless steel sheet with a 3/32" diameter on 5/32" centers hole pattern. The sheet was supported by eight stainless steel bolts, evenly spaced around the perimeter of the strainer, ranging in length from 1" to 1 ¾". I added a ninth bolt in the center of the strainer to add additional support. The tapered height of the strainer created by the progression in bolt length is used to custom fit the strainer to the pot.

There are three important aspects of selecting/designing a mash screen for a RIMS,

The percent open area must be large enough to allow an adequate flow, however, the hole size must be small enough to prevent grain from passing to the pump. The following table shows some typically hole patterns,

I believe the 3/32" diameter hole pattern of the P.B.S. strainer is large enough to allow grain to pass to the pump. The problem only occurs when the wort is first recirculated. The resistance of grain within the pump housing can cause the impeller to decouple from the motor. Typically, the motor needs to be stopped and started, repeatedly, in order to restore the flow of wort.

I believe the .030 slots of the Stoelting mash screen offer a good balance between percent open area and slot size.

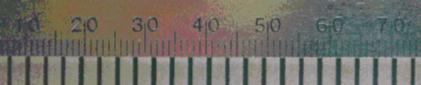

From the picture, you can see that there are exactly 20 "bars" between the measures of 10 and 70 mm, or 3 mm per bar. The advertised bar spacing is 0.030" or,

0.030" x 2.54 = 0.0762 cm = 0.762 mm

The percent open area can be calculated as,

0.762 mm / 3.0 mm x 100% = 25.4%

The mash screen should sit just above the top of the bottom drain.

The Stoelting mash screen legs are 2" high. This is too high

for a Vollrath pot with a ½" bottom drain.

The mash screen must be capable of supporting the weight of up to 20 pounds of grain in 10 gallons of water. I had problems with the P.B.S. strainer buckling with larger grain bills. I believe the buckled strainer allowed grain to pass to the pump. The Stoelting mash screen is extremely sturdy. It can easily support 200 pounds.